However, if you experience significant changes in your operations or costs, you might want to recalculate mid-year. For example, if you add a new production facility, experience dramatic changes in utility predetermined overhead rate costs, or significantly change your production methods, it makes sense to revisit your overhead rate. During that same month, the company logs 30,000 machine hours to produce their goods.

Activity-Based Costing (ABC)

Detailed cost analysis helps to Online Bookkeeping estimate the cost of overheads with accuracy. Further, customized input from different departments can be obtained to enhance the accuracy of the budget. Retail Companies – It takes a lot more than having the product on hand to run a retail business. Retailers need to factor in warehouse rent, staff wages, IT and website developers, advertising costs, and many other costs involved that require consistent monitoring to remain profitable. Although it may feel like extra work you do not want to add to your staff’s plate, calculating project costs after the job is complete is a worthwhile endeavor.

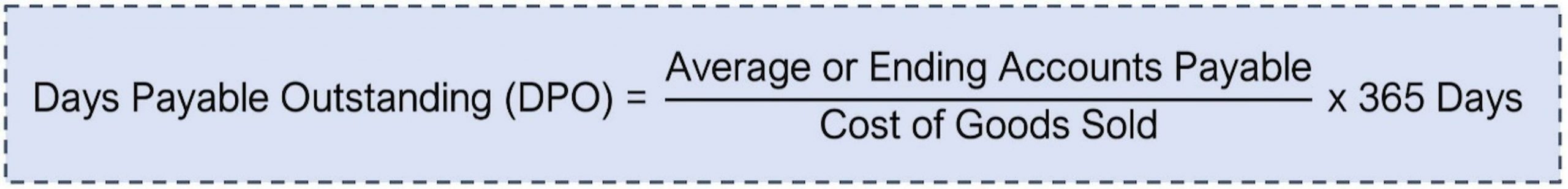

Calculating Manufacturing Overhead Cost for an Individual Job

Overhead is then applied by multiplying the pre-determined overhead rate by the actual driver units. Any difference between applied overhead and the amount of overhead What is bookkeeping actually incurred is called over- or under-applied overhead. The company actually had $300,000 in total manufacturing overhead costs for the year, and the actual machine hours used were 53,000. Predetermined overhead rates are important because they provide a way to allocate overhead costs to products or services. Before the beginning of any accounting year, it is determined to estimate the level of activity and the amount of overhead required to allocate the same. At a later stage, when the actual expenses are known, the difference between that allocated overhead and the actual expense is adjusted.

All inputs in the calculation are estimates.

For example, upgrading to energy-efficient equipment could reduce utilities. Renegotiating contracts with vendors may yield savings on supplies or services. We’re a headhunter agency that connects US businesses with elite LATAM professionals who integrate seamlessly as remote team members — aligned to US time zones, cutting overhead by 70%. Further, overhead estimation is useful in incorporating seasonal variation and estimate the cost at the start of the project. It’s important to note that if the business uses the ABC system, the individual activity is absorbed on a specific basis. For instance, cleaning and maintenance expenses will be absorbed on the basis of the square feet as shown in the table above.

Also, profits will be affected when sales and production decisions are based on an inaccurate overhead rate. Hence, it is essential to use rates that determine how much of the overhead costs are applied to each unit of production output. This is why a predetermined overhead rate is computed to allocate the overhead costs to the production output in order to determine a cost for a product. The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources.

- Whereas, the activity base used for the predetermined overhead rate calculation is usually machine hours, direct labor hours, or direct labor costs.

- Fixed overheads are expected to increase/decrease per unit in line with the seasonal variations.

- The business world is dynamic, and the production environment is getting complex day by day.

- Determining this rate involves identifying various entities, including direct labor hours, overhead costs, unit production, and allocation method.

- Advertising Firms – Marketing and advertising costs may include rent, office supplies, computer software, utilities, internet services, and much more.

- This allocation can come in the form of the traditional overhead allocation method or activity-based costing..

- This method is suitable for businesses that rely heavily on machinery in their operations.

This improves pricing strategies, reduces unexpected variances, and enhances overall financial control. Dorothy’s Hat Company computed a predetermined overhead rate based on annual machine hours. Traditionally, overheads have been absorbed in the product cost based on a single basis of apportionment. For instance, in a labor-intensive environment, labor hours were used to absorb overheads.

Leveraging Accounting Software for Overhead Management

Companies need to make certain the sales price is higher than the prime costs and the overhead costs. In some industries, the company has no control over the costs it must pay, like tire disposal fees. To ensure that the company is profitable, an additional cost is added and the price is modified as necessary. In this example, the guarantee offered by Discount Tire does not include the disposal fee in overhead and increases that fee as necessary. It’s a completely estimated amount that changes with the change in the level of activity.

The company, having calculated its overhead costs as $20 per labor hour, now has a baseline cost-per-hour figure that it can use to appropriately charge its customers for labor and earn a profit. That is, the company is now aware that a 5-hour job, for instance, will have an estimated overhead cost of $100. The overhead rate of cutting department is based on machine hours and that of finishing department on direct labor cost. The total cost of your firm’s billable labor hours is $20,000 and you will bill $2,500 in material costs. These costs are allocated based on the level of activity or resource consumption. It results in a more accurate representation of overhead costs for different production levels.